Closed Containment Salmon Farming Reduces Investment And Operational Risk

Closed containment salmon farming on land, allows Palom Aquaculture to mitigate both investment and operational risk.

Our closed containment salmon farming methodology, or RAS, allows us to quantify and mitigate risk. Below we list each risk and its mitigation strategy.

Closed Containment Salmon Farming -

Risk, Likelihood, Mitigation

1) Risk - Fail to Construct

Likelihood- Low

Mitigation – Hemang Shah successfully manages large water purification projects with UEM. He will oversee construction. The local contractors are reputable, and have been in business for decades, and constructed the RAS systems for the local aquaculture research facilities, CCAR, and USDA. Their bonding capacity exceeds our project costs. All Norwegian equipment vendors must post performance bonds for Palom, Eksportkreditt, and GIEK. All Norwegian vendors have experience working with Eksportkreditt and GIEK.

2) Risk - Construction Hazards

Likelihood- Low

Mitigation - Both local and Norwegian contractors will have health, liability and workman’s compensation policies. Heavy snow loads and rains can make work slow and dangerous. All contractors manage such working conditions. Technologies and construction techniques are known such as concrete, pumps, glass fused to steel/fiberglass tanks, and three-phase electric. Typically injuries are strained muscles and cuts.

Key components such as pumps are over ordered creating a reserve should damage occur during assembly. If needed, this inventory can be immediately used to keep construction on schedule. We do not expect any significant consequences.

3) Risk - Fire

Likelihood- Low

Mitigation - Diesel fuel and electricity are inherently dangerous. Typical safeguards are installed and meet or exceed local building codes and manufacturer codes. During the operation of the farm a control board monitors and controls all equipment. Diesel fuel and generator are stored away from farm building.

4) Risk - Natural Hazards

Likelihood- High

Mitigation - Heavy snow loads and high winds and high waves are frequent. The buildings must meet local codes; the farm is 40 feet above high sea level. The plant shall be designed to address statutory wind, snow, winter weather and other building codes. No high waves have ever been recorded at this elevation. Palom will carry full hazard and crop loss insurance. (see below). Super Chill – This is only a risk for net based farms.

5) Risk - Political

Likelihood- Low

Mitigation - Federal, state, and local administrators issued permits:

1. Discharge Permit - DEP and Army Corp of Engineers have acknowledged that tank construction will survive local weather extremes. Gouldsboro has Prospect Harbor with a significant dilution factor for our discharge that is almost pollutant free.

2. FDA/Dept. of Homeland Security - FDA has on record approved HACCP plans. Homeland Security will request camera surveillance and transparency from eggs to fish.

3. State – Palom will pay above local wages with insurance.

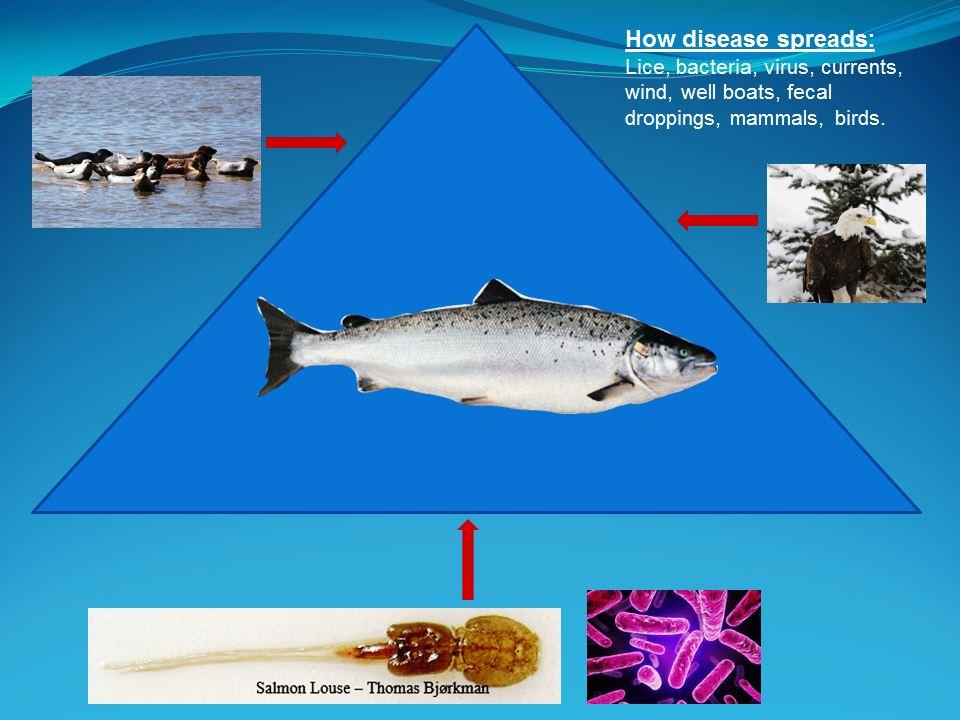

6) Risk - Introduction of Pathogen

Likelihood- Medium

Pathogen Entry Points

Pathogen Entry PointsMitigation – Disinfection Protocols and Physical Barriers

1. Seawater disinfected with filters and UV light before entering tanks. 20 – 40-micron screen sizes will be adjusted seasonally per water conditions.

2. Fences and walls prevent contact with wildlife.

3. All humans and equipment must be disinfected before entering farm building.

4. All equipment is steam sprayed before entering the property.

5. Smolt will be vaccinated. (This is acceptable with Whole Foods and Monterrey Bay Aquarium)

6. All high-risk entrants, like a veterinarian or a feed delivery truck, will receive proper disinfection before entering the closed containment salmon grow out area.

7. Video cameras will record employee following protocols.

8. Video cameras will record fish behavior.

9. New employees will undergo training in pathogen management.

10. We will test fish biochemistry regularly.

11. Water biochemistry will be tested automatically.

12. The feed will be monitored with camera and sensors if pellets land on tank floor system will shut off.

13. We will receive regular notices of infections in the Northeast from other farms.

14. Farm tours will be kept to a minimum.

7) Risk - Complete System Failure

Likelihood- Low

Mitigation – All key components will be controlled and monitored from a central room.

1. Regular employee “walkabouts” are mandatory. Awareness of surroundings is critical.

2. Incidence Reporting System (Go-Canvas) is smart-phone-based. Anything “Strange” will be photographed and immediately sent to a central database for review.

3. Multi-fuel generators will keep all critical components of the closed containment salmon facility running for one week using one tank of fuel.

4. Parts are small enough to be replaced by two employees.

8) Risk - Human Error

Likelihood- High

Murphy's Law Applies

Murphy's Law AppliesMitigation – High paying salaries will attract the best and brightest, but errors will occur.

1. All systems are monitored and controlled by computer control loops, halting catastrophic mistakes.

2. Off-duty employees, all live within one hour of the farm and are on call.

3. Incidence reporting and responses will be reviewed weekly and improved where needed.

4. Incidence reporting system can immediately send problem details to all critical employees.

5. Palom stresses teams versus individuals. Two sets of eyes are better than one.

9) Risk - High Grilse and Mortality

Likelihood- Medium

Mitigation – Documented rates are less than 5% grown under normal conditions in seawater.

High levels occur in artificial sea water and with water temperatures about 15°C. Palom's closed containment salmon farm will use actual seawater and maintain water temperature close to 10°C. Known photoperiods will be utilized. An imbalance in male and female hormones is now being considered the cause. Palom will grow both sexes. Blood incomes will offset higher than anticipated grilse rates.

10) Risk - Complete Crop Loss

Likelihood- Low

Mitigation – All the procedures mentioned will mitigate the loss of the salmon.

Palom will carry replacement cost insurance. Our discussions with insurance companies reveal premiums of about 3% of production costs (value) for conventional net pens. With closed containment salmon farms, some estimate the cost to be closer to 1% of production costs with about 20% deductible. Yearly costs should be from $7,300 to $30,000.

Premiums are front loaded and can be monthly or yearly with a discount. A full audit is needed before the policy is written.

Two of the largest aquaculture insurers: Lloyds, Sunderland Marine Mutual

11) Risk - Feed Price Increases

Likelihood- Medium

Mitigation – We will contract with two suppliers. Corey Nutrition, as it has a Whole Foods approved formula. Corey’s niche is specialized formulations.

Our second choice is Skretting Canada. An international company, they have less variety in feed formulations.

12) Risk - Electricity Price Increases

Likelihood- Medium

Mitigation – Palom has contacted several suppliers of power keeping competition high. To reduce demand fees, we have included multi-fuel pumps and generators to use, if necessary, during peak charge periods.

13) Risk - Salmon Price Drop

Likelihood- Medium

Mitigation – Our cost to grow, including debt service, is 40% of our selling price. We have a substantial buffer should both prices decline and costs increase. Demand for closed containment salmon increases yearly.

14) Risk - Loss of Key Personnel

Likelihood- Low

Mitigation – John designed and built the first closed loop smolt farm in 1984 near Bergen Norway. It was operated for about 20 years. Since the early 1990’s his role within aquaculture has been an outside troubleshooter for banks, insurance companies, and farmers directly. John is the principal partner.

Our first hire will be John’s right-hand man and eventual replacement. In Maine, we have identified four people, with backgrounds similar to John’s, who performed a feasibility analysis about our project. These people have direct line experience with smolt farms and net pen farming.