- Palom Home

- Land Based Salmon Farming

- Ras Aquaculture

RAS Aquaculture Details

Basics Reviewed

RAS Aquaculture - Modular in design, begin small with 5 -6 tanks, max about 18 meters in diameter and 5 meters in height. (A sea inlet pipe would supply sanitized seawater into each tank separately. Each five-tank group would be its own separate "eco-system" as to keep salmon with similar characteristics together, and to use different temperatures for marketing in right time purpose. Each tank would be connected to a mechanical and biological filter to remove uneaten food, fecal matter, and urine and to recycle the material to be used by land farmers.

A Plumbing House - Seawater Movement And Filtration At Its Best

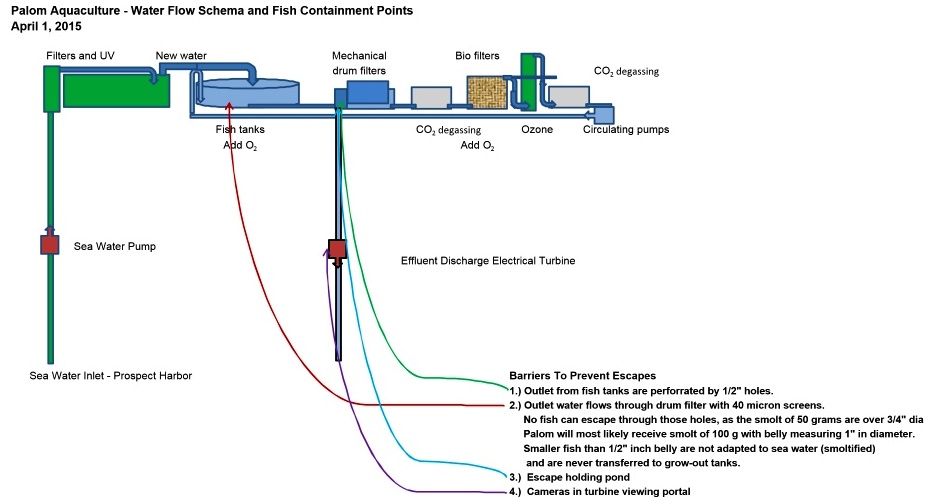

RAS - Simple Diagram Showing Flow of Sea Water (Left to Right)

RAS - Simple Diagram Showing Flow of Sea Water (Left to Right)- Close to the ocean floor in Prospect Harbor, you would pump sea water into a holding tank where filters remove physical debris and particles. Intense UV lights then saturate the water to kill pathogens deadly in RAS aquaculture. (Green - Upper Left)

- The cleaned seawater gently enters the fish tanks which vary circular currents. (Light Blue)

- From the fish tanks, the dirty water enters mechanic filters to remove dead fish, uneaten food and fecal material. (Dark Blue)

- CO2 levels rise quickly from fish respiration and organic material decomposition. Scrubbers or de-gassers, remove C02 from the sea water. (Gray)

- Next water flows through living bacterial filters which convert urine (ammonia) to non-toxic Nitrite and finally Nitrate compounds. (Yellow)

- Scrubbers and ozone gas once again purify the water as it returns to the fish tanks (Gray and Green)

- Less than 5% of total water volume will flow out the farm; 95% of the water will be re-cycled in our closed containment system.

Maintenance Of Aquatic Animals

Temperature

Temperature control is a critical aspect for commercial RAS aquaculture, the temperature is one of the most important parameters for growth. Even a slight temperature change may influence the growth of fish. In a RAS system, temperature can be kept stable through the use of sensors and heat pumps. Temperature of circulating water is preferably to be maintained at 10 Centigrade. Energy transmission from building is not known, and a total energy calculation will be completed when knowing specifications from building supplier. Design flexibility allows for the use of a heat pump to increase or decrease water temperature.

Lighting

It is common in RAS to expose the fish to continuous light. Photoperiod, or alternating cycles of light and dark, may be used for several purposes. If operating a brood farm to get milt and ova year round, light improves the yield as the harvest will go on over the year and tank capacities will be highest. Keeping an operation under 16 hours of daylight and 8 hours of darkness within a 24-hour period, we express as 16/8. The intensity of needed light is small and modern led lamps close to tanks will be sufficient. A continuous light regime is part of a strategy to avoid early maturation.

Salinity

Salinity is traditionally defined as the total amount of solid material, mostly ions, dissolved as parts per million in an amount of sea water. In open oceans, this may be up to 40 at the surface. In coastal areas, say 25. A constant salinity is positive for the growth of fish as it is not affected by a change in this environmental parameter. A sea pen farmer has no or less control over the salinity (he may pump water from the deeper sea). In RAS aquaculture, salinity may vary a little over the year, but in general, it is considered to be stable. Salinity may be complicated to determine and is not to be understood as density or specific gravity.

For practical daily use, specific gravity is quick to measure and also indicates the value of salinity.

Oxygen

Water contains much less oxygen than air at a given partial pressure, and aquatic animals must breathe 10 – 30 times more than the volume of air breathed by terrestrial animals to obtain the same amount of O2. It is critical to keep the O2 level as high as possible, and it is measured as mg/l or as percent saturation. Sea water for salmon should not contain less oxygen than say 6 mg/L, so this will be the approximate level at discharge and at the tank outlet. At tank inlet, O2 is being kept at a high enough level to satisfy fish consumption, and being at the lowest level at discharge. At 75 % saturation, less appetite will appear and at 60 % possible mortality will be noticed. Inlet water may contain 100 – 120 percent saturation, not being supersaturated. A sea pen farmer has no control of oxygen, unless he pumps water from the deep or uses an aerator. In RAS aquaculture, the farmer has a total control of oxygen supply to the fish. Oxygen may be produced by generators on the farm or purchased. This farm will have several oxygen generators, producing our own oxygen. Oxygen diffusers are being stored for emergency use and in cases like grading.

Solids Removal With Mechanical Filters

The type of filter planned is the French type Faivre Sarl, model 32-160. These are drum filters made of acid-proof steel. Other filters are available, and some have been tried, but these are found by experience to be the most satisfactory due to analysis of farms in Norway. The filters are placed in the bio-filter room, as it is considered an advantage to keep as much as possible of technical installations out from production hall. This has to do with practical things as use of tools; lifting equipment; intermediate storing and cleaning; a better overview at elements in operation; noise and in that respect: communication and working environment in production hall.

Plastic Material Upon Which Bacteria Grow

Plastic Material Upon Which Bacteria GrowBacteriologic Filtration - Breakdown of Ammonia

The bacteriological activity occurs inside films established on material surfaces all over the plant. It is evident that we need large surfaces, which cannot be satisfied by a tank or tube walls. To achieve a large surface, components with a large surface is concentrated in the two above named bio-filters. The parts are called bio-elements. Plastic elements with a surface of 800 – 1,500 m2 per m3 of elements are being used. An aquaculture recirculation biofilter must be large enough to handle the fecal and feed remains from fish tanks, or it will crash. For the Palom closed containment farm, the area of bio-filters is extended by 50 % more than calculated area. Besides, the tanks containing the bio elements are capable to receive three times more –bio-elements than are built in.

Feeding - Less Is More

The number one rule in RAS is “DO NOT OVERFEED.” It should be obvious to anyone that overfeeding leads to crashing of bio-filters. Due to this fact, feeding is being more focused in RAS aquaculture than in a sea pen operation. Sensors will detect if only one feed pellet sinks to the bottom of a tank and feeding will automatically be reduced or stopped. As feed is the major cost, there will be large savings of feed by using adequate equipment for feed control. Feed suppliers will be Skretting and Corey Feeds.

Feed is automatically distributed to tanks, individually adjusted to the need for each tank. Workers controlling and adjust on a computer in control room or done on-line by a laptop if the manager is off the farm.

Nevertheless, how good a plant is of design, the operator must have a good understanding of basics.

Fish may live for a year or longer not being fed, so fish will not suffer by a non-feeding period if needed for maintenance, etc.

Exercise

Salom naturally swim against the current. Exercise maintains ideal fish health. RAS can maintain an ideal water speed of about 1.0 to 1.5 fish length per second.

RAS Aquaculture - Biosecurity

Biosecurity is the set of practices that minimize the risk of:

- Introducing an infectious disease to the farm

- Spreading the infectious agent to the fish at the farm

- Transferring infectious agents to other sites and other susceptible species

- Reducing fish stress, thus making them less susceptible to disease and more desirable to Palom’s customers.

Biosecurity goals are:

- Fish Management—obtaining healthy smolt stocks, optimizing their grow-out through good husbandry and best available technology of our contained RAS.

- Pathogen Management—preventing, reducing or eliminating pathogens

- People Management—educating and managing staff and visitors.